Industry 4.0 – CPQ software for forklift trucks (VNA)

Buzzword: Sales 4.0?

Manufacturers of forklift trucks in nowadays use highly qualified experts in the worldwide field service for consulting and analysis at the end customer. Due to the change to ever larger and increasingly technologized warehouses with the use of simple, free-moving floor conveyor vehicles up to completely process-integrated narrow-aisle vehicles, the “vendor’s tray” of a system consultant is permanently filled with further products. In order to avoid losing the overview here, so-called CRM and configuration tools are provided.

CRM systems “administer” the customers of the system consultant and can be used as a support for the preparation of quotes. In addition to this, the so-called configurators are used, which we encounter every day. Whether as a customer in a furniture store or on the Internet on one of the well-known car manufacturer sites.

When considering highly complex narrow aisle vehicles, several factors must be considered by the “expert” when designing the vehicle:

The vehicle: Should it be a pure order picking vehicle, a so-called “combi stacker” or a man-down device?

The type of guidance: Does the customer require a rail-guided or induction-guided vehicle? Or was a free-moving commissioner requested?

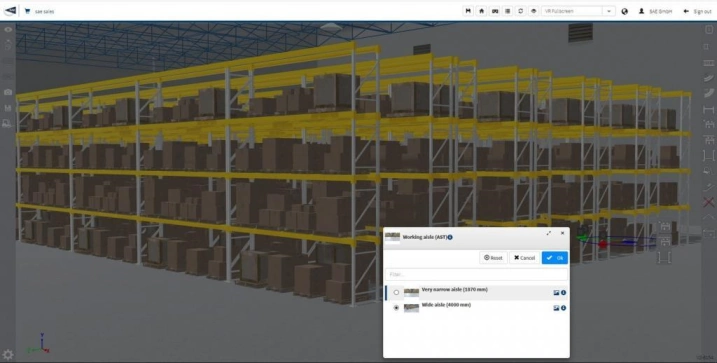

The warehouse/building data: How wide are the aisles? How high are the doors under which the driver may still have to pass? How high is the building? How many kilograms have to be lifted to which shelf height?

The load: Which loading equipment does the customer use? Does it possibly have different loading aids, for example, a Euro pallet, a mesh box and/or an industrial pallet?

In addition to the above, other factors now come into play, such as the calculation of residual carrying capacities as well as time differences due to countries located at the other end of the world. This makes it difficult to call back to the specialist departments in the individual production plants and is not efficient nowadays. The customer expects a high-quality quotation with all details promptly from all suppliers.

How does the system consultant ensure buildability and plausibly that his offered inductive guided combination stacker fits into the warehouse and that the residual capacities have been calculated correctly? How will the current buzzword “Industry 4.0” soon become a new buzzword: “Sales 4.0”?

Example of a real inquiry

SAE GmbH, a software manufacturer and specialist in variant data management with over 20 years of SAP experience, has the solution approach – based on the example of a real customer inquiry – in its baggage.

The starting situation: SAE GmbH was selected to bring the entire “knowledge” of the development and engineering departments to the notebooks and tablets of the sales colleagues working around the world.

The target had been clearly and unambiguously formulated: “No separate maintenance of existing procedures, object dependencies and calculations in another system, complete off- and online availability.” This is the only way to ensure that all changes in the variant management of the industrial trucks remain under the sovereignty of the manufacturer’s development department. There is no need for maintenance or so-called matching of data in marketing or product management.

The challenge: The complexity of a so-called narrow-aisle stacker with more than one billion possible combinations. Here, buildability in the factory and plausibility on-site at the end customer must be 100 percent guaranteed. This can only be achieved if the existing data is not changed.

For reasons of complexity, sovereignty always remains with the development engineers. The dependencies, procedures, and object dependencies defined there can be easily loaded into the SAE variant data management platform using the standard interface “SAE Sales Interface” and made available immediately online or offline to global sales. Additional requirements in this project were the integration of a product finder, an interface into the existing CRM system, and the automatic back-transfer of the worldwide orders into the SAP ECC or S4H system of the order processing centers in the respective production plants.

Project procedure

SAE’s quotation and configuration system was used. The requirement was that SAE had to prove within a few days that the existing data could be read into the SAE system and that within the shortest possible time the SAE configurator and the SAE product finder would be functional. This approach is offered by SAE to all customers to immediately ensure successful project implementation. The company believes that this is the most honest and reputable way to make it easier for customers to enter into a long-term partnership.

SAE had implemented all of the customer’s specifications within a very short time. Any user of the SAE quotation and configuration system can “find” and then configure a highly complex narrow-aisle truck within two minutes using the implemented product finder. He is guided through the system, enters six to eight so-called must-have features, and immediately receives the matching vehicle, including load capacity calculations and dimensions. SAE then “inherits” the product finder class into the vehicle configuration and the user then still clicks on the desired options that their customer needs. However, only options that actually exist for the “found” vehicle are displayed here. The subject of Sales 4.0 is increasingly coming into focus as a result of such implemented practical examples. Using this developed SAE interface, any system consultant can immediately jump from the CRM to the product finder, “find” the corresponding forklift, and then start with the proper configuration. Process reliability – from the quotation phase to the order and subsequent order in the production plant – is 100 percent.

As a result of this implemented project, the customer has quoting/configuration software in use around the world that allows any system consultant to instantly quote even the most complex material handling equipment in over 20 different languages within two minutes. All quotations contain full buildability and plausibility, there are no queries or – in the worst case – a delivery of expensive narrow aisle vehicles which cannot be used at the customer’s site. Customer consultants can work offline and online and have more than doubled order intake, in the narrow aisle vehicle sector alone, in four years.

Digitalization in sales with SAE CPQ

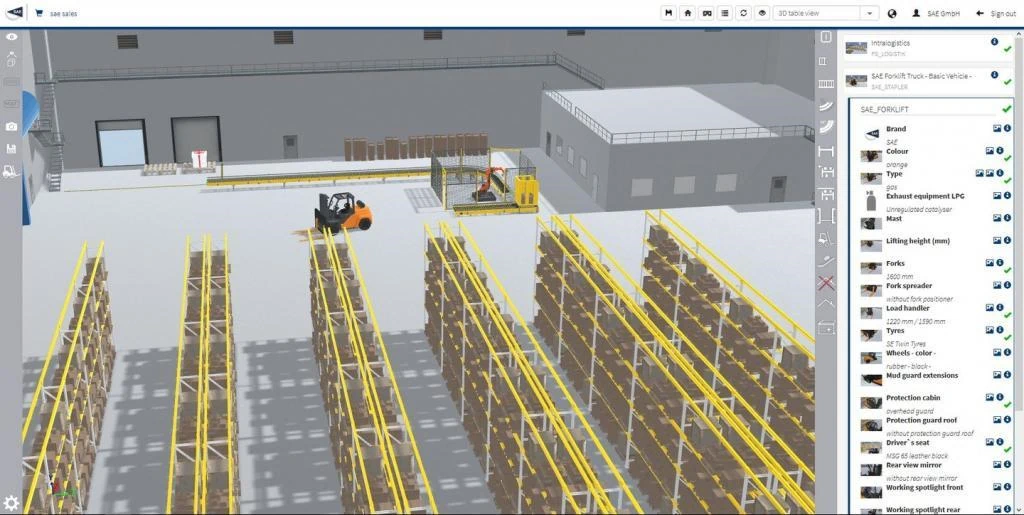

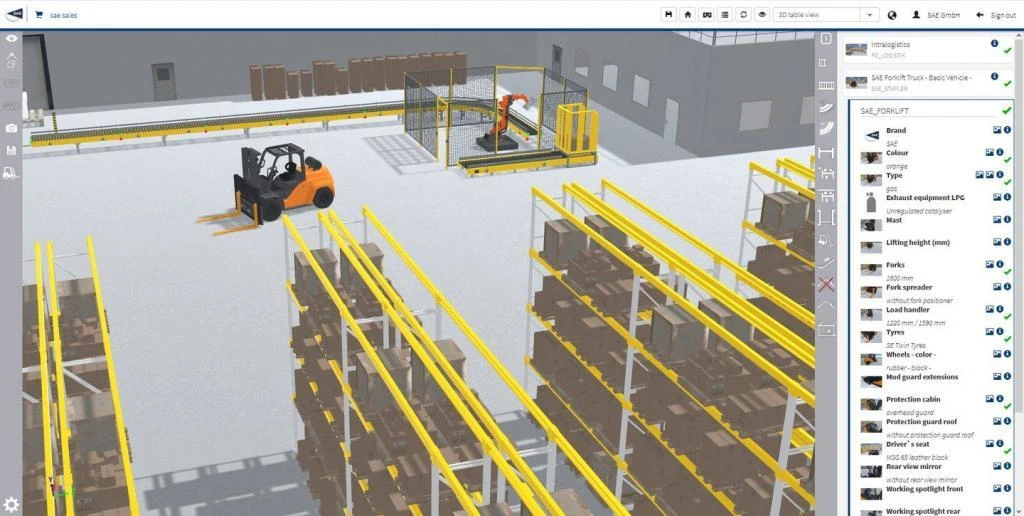

SAE has developed an outstanding solution for high-end sales. The sae interactive motion engine offers fully animated 3D visualizations that can be interactively evaluated in the configurator or in the visualization. This means that the product evaluation can be modified and carried out either in the model in the configurator or alternately. For example, entire plant systems or hall planning can be created by the sales department. No expert knowledge such as design or product know-how is required.

The highlights here are the fully movable models so that the function or collision check also takes place automatically. The digital twin is fully web-enabled, contains no design data (data security in global sales), is easy to operate via guided configuration or interactively in the model. Outstanding is the extremely short project realization. The customer gives SAE his design data and within one working day, he can use his model in the “interactive motion engine” in sales.